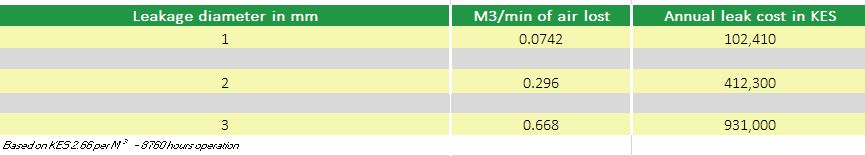

What is the cost of a leak?

The table above shows leakage volume for different sizes of leak diameter and the related costs.

For many this chart is somewhat of an eye-opener to the enormous cost and the exponential effect of “small” leakages and how it affects cost. Becoming aware of the true cost of compressed air is at the very core of managing compressed air and understanding the problem.

Without an established cost compressed air remains a free resource, without any incentive to reduce its consumption. In 2021 we still find companies that have leakage rates between 25-50%.

What other resource of such magnitude is such waste allowed and why?

Imagine a supplier continuously delivering only 70% of the invoiced amount, how long would that relationship last with any form of accountability? Yet, that is exactly what is happening for many companies.

Now that you understand how expensive your compressed air is. What next? We recommend training your team on the basics of compressed air costs and safety.

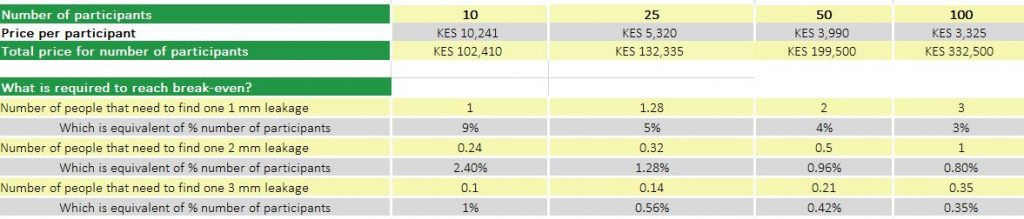

What is the payback period for Training costs?

Training is the logical first step when you want everyone to be on-board and singing from the same hymn sheet. Our on-line course in partnership with LMSNordic creates awareness of how compressed air affects costs, sustainability, safety, working environment.

However, the first question for many plant managers will be; what is the cost and benefit of the training? Would you believe that the full cost of 10 participants could be paid for by the annual savings from 1 participant finding and repairing a 1mm leakage. The payback become even more attractive if an attendee finds and repairs a larger leak.

After doing the course and getting back to their work station or machine, each participant is tasked with finding leakages, unnecessary blowing, etc. and report these in the training system. That means you can track the savings.

If 5 people report they found two leakages each and were able to reduce pressure etc, we can get a pretty good idea of what that means in volume and monetary terms.

See the table below for your payback period.

Start today with our Compressor online training package

Includes:

- 30 minute online training tailored for delivery to between 15-25 employees.

- Log in details are provided for each attendee and are valid for 3 months.

Feedback module for each attendee to log leaks found and repaired and other energy savings initiatives. You can track the impact of the training.

To find out more about our training services, click here.

info@ren-engineering-solutions.com

Call/WhatsApp 0741159200