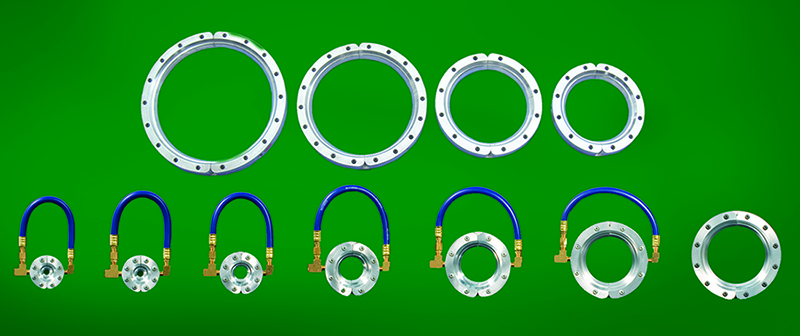

An air wipe is a compressed air product ideal for blow off, drying, cleaning and cooling operations. It provides a uniform 360° air stream for cleaning both circular and extruded shapes.

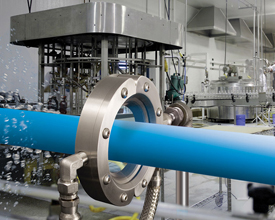

Drying large diameter pipes

How the Super Air Wipe Works

Design

It has a split design which provides easy clamping around surface of the material moving through it & eliminating product damage. EXAIR air wipes come in different diameter sizes ranging from to 3/8’’ to 11’’.

It also comes with shims that are placed on a gap between the cap and body through which air is exhausted which can be added or removed, depending on the amount of force and flow that you require.

Why Choose EXAIR Air Wipes

Prior to introduction of air wipes, the only way to clean round cylindrical or extruded shapes was the use of a ring of air nozzles whose air consumption is very high alongside inconsistent air velocity delivering poor results. EXAIR air wipes provide:

- High volume

- High Velocity(variable from Blast to Breeze)

- Uniform air flow through 360°

The Super Air Wipe is very efficient with minimal air consumption and above all, noise levels that are low ensuring a safe working environment.

CASE STUDY

BEFORE EXAIR

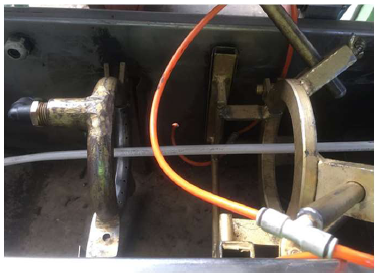

We visited a factory in Nairobi that used two locally fabricated air wipes to dry electrical cables.

It was noted that:

- Most of the original air wipes were not working and had been replaced by local modifications.

- Both locally fabricated air wipes took in compressed air at full pressure with no pressure regulator.

- The first air wipe had 4 holes drilled into a circular pipe. Each hole was approximately 4mm or 1/6”. The compressed air consumption from each hole 3 cfm x 4 = 12 cfm or 5.66 l/s at 5.5 bar.

- The second air wipe had approximately 20 holes in a cylindrical pattern. Each hole had a diameter 4mm bringing the total air consumption at 5.5 bar to 3 cfm x 20 = 60 cfm

- Total air consumption of the two air wipes is 72 cfm or 33.98 l/s at 5.5 bar

- Note that wiping is not sufficient, and foam had to be used used to ensure that the wire was dry.

Our main objective was therefore to reduce the volume of compressed air usage and save the company money.

AFTER EXAIR

The EXAIR Super Air Wipe replaced both the fabricated air wipes and the sponge.

- We installed 3”(Model 2433) internal diameter Super Air Wipe which provided effective drying with an air consumption of 39.8 cfm or 45% less compressed air.

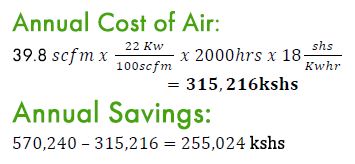

- The savings from replacing the locally made air wipes with the new 3” air wipe operating for 1 year (4000 hours) were calculated as follows.

- NB: The specific energy of the compressed air is at 22 Kw/100 cfm.) (1 l/s = 2.12 scfm)

- The cost of a new standard 3” air wipe was 93,000 for a payback period of 1.7 months

- Noise levels also reduced from over 100db to 80db.

If you’re processing any type of hose, wire, or extruded shapes that could benefit from installing a Super Air Wipe give us a call.

Contact us for a site survey Call NOW! 0741159200!