Are you working in an industrial setting? Do you work with pneumatic tools? Do you work around automatic systems? Are you in need of a compressor that will provide compressed air for your application but are not sure which one to go for? At Ren, we are here to help you make the right decisions.

Many compressed air users tend to buy a compressor without understanding how to select the right compressor for their application. The wide range of compressor types currently in the market may make it a little difficult to select the right one. This article will help you simplify the process of selecting the right compressor and accessories through our easy 4 step process.

Easy Four Step Compressor Selection Process

Power Applications

Process Applications

Instrumentation/Control Applications

Flow and Pressure Requirements

After contacting our representatives, you will get a free site survey. The following four step process allows us to narrow down and select the right equipment for your application.

STEP 1: Understanding your compressed air application

Compressed air applications are mainly categorized under process air, control/instrument air or power applications.

- Process air is used as part of production process

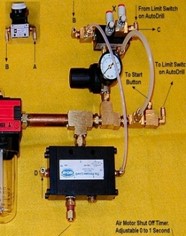

- Control/instrument air is used to automate processes i.e (with pneumatic valves),

- In Power applications compressed air is used blow molding or pneumatic power tools (e.g. riveting guns, jack hammers).

Its important that we understand where your compressed air use falls under any of the three categories.

STEP 2: Total flow rate requirement

Calculating the total flow rate requirement from all your equipment helps select the right compressor size that will meet this demand.

STEP 3: Pressure requirement

Checking the pressure requirement is important as it will help in selecting the compressor that can meet the pressure demand for your equipment.

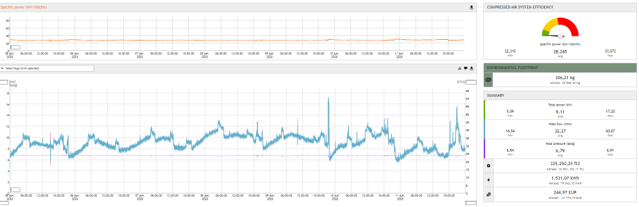

STEP 4 Energy efficiency

When selecting the compressor, we check for the one which will have a high energy savings motor that is from iE2 to iE4 which will give a payback period of less than 3 years when upgrading.

Why work with Ren?

REN is an engineering and services company that provides you with the best compressed air solutions. Part of our success has been in helping clients select the best compressor for their application and providing installation services. Our work has helped clients save on air consumption which resulted in a subsequent saving of energy consumption and ultimately save on money.

Recently, one of our clients needed a compressor for their workshop to operate some of their pneumatic tools which falls under power applications. Our team carried out a site survey and found that the pressure requirement was a 7 bar for their equipment and a flow rate of roughly 36 scfm.

From the data obtained at above, we were able to recommend to the client 7.5 Kw (10 hp), highly efficient oil injected piston compressor. The selection of a piston compressor was because the use of compressed air for this client was intermittent.

A filter was installed after the compressor to ensure quality of air matched the application requirements. The compressor was also able to meet the customers pressure requirements comfortably.

By

Sylvia Chemonges, Projects Engineer

Contact us for a site survey or installation. Cal NOW! 0741159200!

One Reply to “HOW TO: select the right compressor for your application”

do you supply only or instal and provide back up services and regular maintenances?

if i want a survey done at our factory, do you charge for the survey? if yes, how much?