So, just how do you select the correct size of compressed air piping for your plant? From experience, it is still common to find installations with undersized compressed air piping. Undersized pipework leads to high pressure drop leading to high energy bills.

Components of a compressed Air System

A compressed air system consists of the three primary sub systems the supply side, demand side and distribution network.

There are different types of pipe material that you can select to supply compressed air depending on your application (we will leave the discussion about the types of compressed air piping is for another day). Regardless of the pipe material selected, the demands placed on the piping are the same. Therefore, it is important to research and select the right piping size for your application.

What is the effect of pressure drop along the line?

If the pressure drop in your compressed air system is too high, then you automatically increase the pressure set point at the compressor room.

Increasing the pressure set point translates to higher energy consumption. The rule of thumb is that for every 1 bar pressure increase you get a 7% power consumption increase at the compressor. This increase in energy consumption does not consider the energy losses due to increased air consumption in the plant caused by artificial demand. Artificial demand is where machines consume a higher flow rate for the same work simply because the supply pressure is higher than required.

The target pressure loss for your system should be no more than 0.3 bar. That is, if your compressor outlet produces 7 bar, then the pressure at the machine point should be about 6.7 bar. This minimum 0.3 bar loss is caused by air pressure drop through the dryer and filter and other fittings before reaching the demand point.

Selecting the correct pipe size

It is also worth noting that, selecting the proper pipe size depends on two main factors. They are:

- Distance from the supply to demand

- Volume(flow rate) of air required by the machines.

For the same flow rate the pipe size required to supply compressed air for a point 200m away would be larger than one supplying 5 m away. This is because the further you go the higher the pressure drop along the line due to friction losses and the effect of turbulence caused by fittings such as elbows and valves.

To select the correct pipe size, follow these steps

1. Check for the total flow rate required by your machines.

This is done by summing up the flowrate requirement by individual machines.

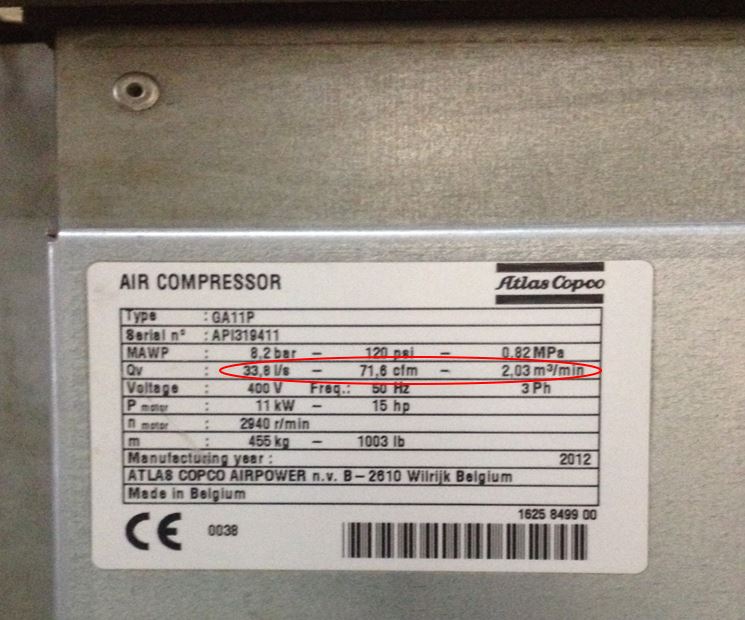

For those who already have a compressor at site, use the data plate on the compressor to get the total flowrate supplied. (See figure 1 below)

The flowrate could be in liters per second (l/s), cubic feet per minute (cfm) or cubic meters per minute or per hour (m3/min, m3/hr.). The figure below shows an example of flowrate data on a compressor data plate.

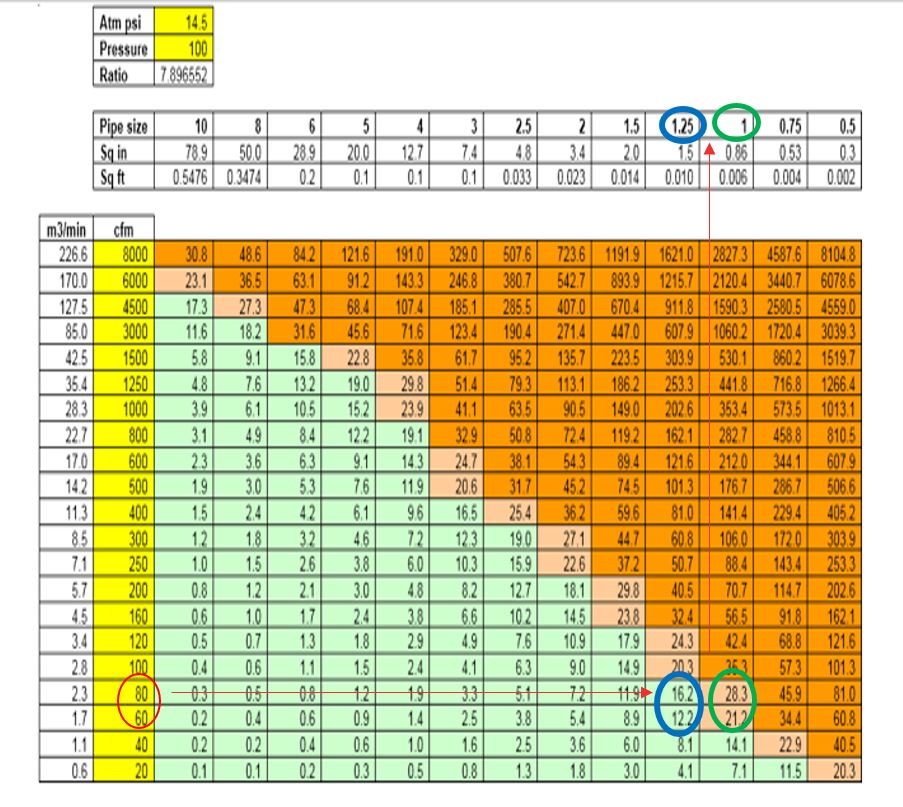

2. Take the flowrate data and use the compressed air chart showing air velocity(feet/second) depending on the pipe size.

For laminar flow to occur in the pipe, the velocity of compressed air should not exceed 30ft/s.

For example, in the compressed air system above, the flowrate is 33.6 l/s or 71.6 cfm

71.6 cfm falls between 80 and 60 cfm. From the Figure 2 above. Starting on the second column with flow rate in CFM. Move horizontally towards the right. The colored boxes show the velocity of air in feet per second. Once you reach the light orange boxes you move vertically upwards to select the correct pipe size in inches. Thus, the velocity of compressed air for a flow rate of 71.6 cfm falls between 21.2 and 28.3 ft/s for a 1” pipe and 16.2 and 12.2 ft/s for a 1.25” pipe.

The deep orange zone of the chart shows that air velocity in the pipe is above 30 ft/s and this would result in a high-pressure loss. For example, if a ½” pipe or ¾” pipe were selected for the flowrate specified.

The green zone of the chart shows the pipe size that would be ideal depending on the flowrate. Both the1” and 1 ¼” pipe are fit for purpose since velocity is below 30 ft/s and they are not oversized.

We hope that you now know how to select the correct pipe size for your plant. We look forward to discussing the type of material you should use.

Feel free to send an email or share a comment if you have any inquires.

Sylvia Chemonges

sylvia@ren-engineering-solutions.com

Call/Whatsapp 0741159200

Find out more about our installation services click here